Cold chain monitoring IoT

Cold chain monitoring IoT is a temperature-controlled supply chain comprising refrigerated production, storage and distribution facilities supported by equipment that can constantly maintain the required low-temperature range. However, it’s far more complex than it sounds. For example, some vaccines require a constant temperature range from the time they are manufactured until they are used.

The requirement is so exact that if the temperature goes outside of this range, even for a short time, the vaccine could lose its potency and become unfit for use.

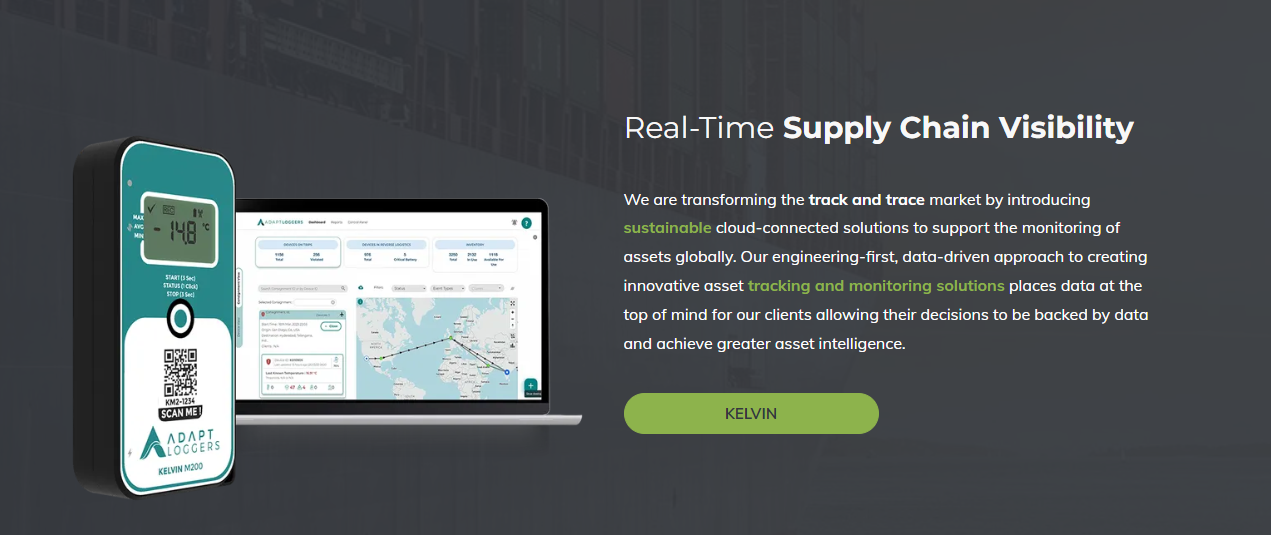

We specialize in all types of item, personal and equipment tracking for all industries.

- Cold Chain for Pharma and Specialty goods

- Cold Chain for Food, Beverages and Processed items

- Cold Chain for Monitoring Data Centers and equipment

- Cold Chain for agricultural produce, seafood, frozen food, photographic film, chemicals and more.

Industry: BioPharmaceuticals

BioPharma waste is 25% of global production each year Source: UN REPORT 2016

The pharmaceutical industry is estimated to be worth USD $1170 billion as reported by the Business Research Company. With the industry continuously growing each year, this highlights the increasing need for the pharmaceutical industry to protect its high value and temperature-sensitive products throughout the cold chain to ensure that they reach clients and end-users in the same condition that they have left in.

Biopharmaceuticals are highly sensitive and can be impacted by a variety of factors within the cold chain. Temperature fluctuations, exposure to light and even shock can affect biopharmaceuticals impacting their viability, and at times rendering them unviable for use.

Biopharmaceuticals within the cold chain can require different cold chain management capabilities. Innovative asset tracking solutions are vital to cold chain management allowing operational efficiency and supply chain visibility to be improved. Many countries globally are implementing standards that set out to improve the monitoring and tracking of pharmaceuticals.

This includes The Australian Code of Good Wholesaling Practice for Medicines, which sets out guidelines that must be complied with by all third-party associates. The code highlights that temperature-sensitive pharmaceuticals during transport should be monitored to ensure that the conditions outlaid by manufacturers are being met. In the United States of America, the FDA enacted the Drug Supply Chain Security Act in 2015, to establish the mandatory tracking of all pharmaceuticals from 2023 onwards.

These trends indicate that the global pharmaceutical industry is placing greater focus on ensuring an end to end visibility is present during the supply chain. A report released by the IATA on pharmaceuticals found that pharmaceutical degradation occurs most commonly during shipping and storage.

A further report by IATA stated that the pharmaceutical industry loses $2.5 billion to $12.5 billion annually because of problems with cold chain management during logistics. This further highlights that solutions need to be innovated to increase supply chain visibility, operational efficiency and reduce instances of waste and damage for the pharmaceutical industry.

Current Measures

Biopharmaceuticals are highly sensitive and can be impacted by a variety of factors within the cold chain. Temperature fluctuations, exposure to light and even shock can affect biopharmaceuticals impacting their viability, and at times render them unviable for use. Biopharmaceuticals within the cold chain can require different cold chain management capabilities. Innovative asset tracking solutions are vital to cold chain management allowing operational efficiency and supply chain visibility to be improved.

Pharmaceutical Temperature Monitoring

Fluctuation in temperature can have determinantal effects on pharmaceuticals falling outside of certain temperature thresholds can impact the viability of pharmaceuticals, decrease their potency even impact the health of a consumer. Supply Chain Intelligence gathered from IOT.

Common Challenges In Cold Chain

Many countries globally are implementing standards that set out to improve monitoring and tracking of pharmaceuticals, which sets out guidelines that must be complied with by all third-party associates. The code highlights that temperature-sensitive pharmaceuticals during transport should be monitored to ensure that the conditions outlaid by manufacturers are being met. In the United States of America, the FDA enacted the Drug Supply Chain Security Act in 2015, to establish the mandatory tracking of all pharmaceuticals from 2023 onwards. These trends indicate that the global pharmaceutical industry is placing greater focus on ensuring an end to end visibility is present during the supply chain.

Food and Beverages

Food and beverages waste is 1/3 of global production each year

Cold Chain Tracking and Monitoring for Health Care

Real-time data loggers offer several advantages over traditional data collection methods, making them valuable tools across various industries. Here's how they bring tremendous benefits:

Increased Efficiency and Cost Savings:

- Automation: Real-time data loggers eliminate the need for manual data collection, freeing up personnel for other tasks. This reduces labor costs and improves overall efficiency.

- Continuous Monitoring: They can capture data constantly, providing a more comprehensive picture compared to periodic manual readings. This reduces the risk of missing important trends or events.

Improved Data Quality and Accuracy:

- Reduced Human Error: Manual data collection is prone to errors due to fatigue, miscalculations, or transcription mistakes. Real-time loggers eliminate this risk by automating the process.

- Timely Insights: Data is transmitted and displayed in real-time, allowing for immediate analysis and response to critical situations. This is crucial for applications where quick decisions are necessary.

- Enhanced Safety and Process Control: • Early Warning Systems: Real-time data loggers can be set with pre-defined thresholds. If readings exceed these limits, they can trigger alarms, allowing for prompt intervention and preventing potential issues.

- Remote Monitoring: Data can be accessed and monitored from any location with an internet connection. This is particularly useful for applications in remote or hard-to-reach areas.

- Compliance: The Good Distribution Practice (GDP) guidelines for medicines and the Hazard Analysis and Critical Control Points (HACCP) for food safety are only two examples of common laws and regulations that businesses must follow.

Applications Across Industries: Real-time data loggers find use in a wide range of fields, including

- Environmental Monitoring: Tracking temperature, humidity, and air quality in buildings, greenhouses, or for pollution control. • Healthcare: Monitoring vital signs of patients in hospitals or remote care settings.

- Agriculture: Tracking soil moisture, temperature, and weather conditions to optimize crop yields.

- Manufacturing: Monitoring equipment performance and production line efficiency to identify and address potential problems quickly.

Overall, real-time data loggers provide a powerful tool for continuous, automated data collection, leading to improved efficiency, better decision-making, and enhanced safety across various industries.

Perishable food & beverages are largely prone to experiencing temperature excursions due to incorrect handling and ineffective cold storage & logistics processes amongst other reasons.

A study released by the Food and Agriculture Organisation in 2019 (FAO) found that 14% of all food wasted occurs between harvest and retail further highlighting the need for a solution to consistently monitor perishable foods and beverages during transportation.

Globally the industry is under increasingly stricter regulations such as the FDA’s Food Safety Modernization Act (FSMA).

Additional regulations are just one aspect that is affecting the food & beverages industry. Sustainability is another increasing pressure the industry is facing with large amounts of food & beverages going to waste every year.

Greater supply chain visibility of high-value products in the industry can assist in reducing levels of perishable food waste.

Visibility can be achieved with the implementation of IoT enabled asset tracking solutions throughout the supply chain.

In addition, environmental monitoring systems can also be implemented for monitoring vital conditions of perishable food & beverage products in cold storage facilities.

The perishable nature of seafood and meat makes them significantly at risk of experiencing cold chain breaches and products being incorrectly handled leading to a deterioration in quality or product and packaging damage during the supply chain. This can lead to products no longer being able to be consumed therefore resulting in higher levels of waste.

The utilisation of asset tracking and monitoring solutions can assist companies in this industry to increasingly meet compliance and regulations that are place by industry bodies and governments. With Adapt Ideations’ products sharing data with clients can be achieved easily allowing concerned parties to always understand how the products have been handled and stored.

Intelligent Dataloggers for all Asset Tracker

Monitor valuable cargo on the move with near-real-time location, temperature and tamper detection to greatly help improve compliance during transport and reduce wastage.

Use Case for Dataloggers

- Vaccine & Medication.

- Specialty Pharma with Insulted Packaging.

- Temperature monitored Food & Beverages.

- Data Center Equipment.

Key Features

IntelliStride Intelligent Datalogger Devices Key Features

- Intellistride Intelligent Datalogger Devices support shipments that are worth thousands of dollars making it essential for our clients to track every essential vital sign of the cargo.

- Tracking every High-value shipment in your cold chain operations can reduce loses through fast resolutions.

- This could involve delays in transportation, issues experienced within the cold chain and even theft costing huge losses during shipment. In most cases of cargo mishandling, this increases wastes which is not eco-friendly and impacting longer term client relationships and company reputation.

- Intellistride.com

- IoT solutions

- Cold Chain Solutions

- Start Free Trial